HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

What is HACCP?

Hazard Analysis Critical Control Points (HACCP) is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed.

HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Today, many of the world’s best manufacturers and vendors use the system as a basis for their food safety management programs and for compliance with GFSI audit schemes. Global Food Safety Initiative (GFSI) Certification. Due to complex challenges in today's food supply chain, many of the world's largest food retailers are mandating supplier certification to Global Food Safety Initiative (GFSI) schemes, which include SQF, BRC, IFS, FSSC, GLOBALG.A.P. and BAP and CanadaGAP.

Through analysis of hazards and where they can occur, Safe Food Alliance of California helps implement systems and procedures to minimize risk. Safe Food Alliance provides a truly hands-on food safety management system at each and every operation in assisting in the management of critical control points.

A food safety program, however, does not just stop with HACCP. To be effective, prerequisite programs such as pest control, traceability & recall, hygiene and sanitation need to be developed and implemented. Additionally, the issue of ensuring that suppliers and distributors also have a food safety program needs to be addressed through development of ingredient specifications and a vendor assurance system.

Why is a HACCP Plan Important?

Proper implementation of a HACCP program helps reduce the likelihood of customer complaints or a recall by identifying and controlling potential hazards which may come from raw materials, facility processes, and human error. The greater employee awareness that results from a HACCP program helps to drive continual improvement of a company’s products and processes.

Additionally, the HACCP principles are in alignment with the requirements of the FDA’s (The Food and Drug Administration is a federal agency of the United States Department of Health and Human Services, one of the United States federal executive departments )Food Safety Modernization Act (FSMA) rule for food processors — Hazard Analysis and Risk-based Preventive Controls (“HARPC” or “Preventive Controls”). Although a HACCP plan does not meet all of the requirements, it meets the majority of the requirements and is the best platform from which to build a FSMA-compliant management system

Why need of HACCP Certification ?

In food safety management a fundamental approach to managing risk is implementing a HACCP system. This acronym stands for Hazard Analysis and Critical Control Point. It is a system that identifies, evaluates and controls hazards that are significant for food safety.

Thinking about HACCP Certification for your business? We’ve come up with our Top 5 reasons why your business should be looking at HACCP certification. In food safety management a fundamental approach to managing risk is implementing a HACCP system. This acronym stands for Hazard Analysis and Critical Control Point. It is a system that identifies, evaluates and controls hazards that are significant for food safety. But it’s not uncommon for organisations who don’t handle food to be asked for HACCP certification; any organisation in the supply chain could be asked by their customers or clients for HACCP certification.

1. Provides confidence around the safe production of food

Often a starting point for an organisation is that a customer has requested that they are certified. Why is this the case? To receive certification an organisation needs to demonstrate it has processes in place to identify and control any food safety risks. This capability is reviewed by an independent third party prior to any certifications being issued. This is where the value in the certification lies. Consumers and customers can take assurance that the processes in place meet the requirements of established best practice.

2. Access to an increased market

As certification is a requirement for many potential customers (refer point 1 above) organisations find there is access to a greater market once they have certification. It is also something that can be used in marketing to try and gain some of that market opportunity.

3. Enhanced Reputation

One of the major risks to an organisation is a loss of reputation. Imagine the effect of an organisation that has an incident with its food handling that impacts on its customers and ultimately consumers. Food safety management helps establish a risk management framework to prevent a major loss of reputation.The other side of this is that having Food Safety Management certification helps enhance the reputation of the organisation due to the confidence it gives consumers and customers (refer point 1)READ A quick guide to getting HACCP food safety certification

4. Improved efficiency reduction of waste and re-work

As with any good quality and risk management process, waste is identified and taken out of the process. This helps organisations achieve the benefits of improved efficiency.

5. Employee awareness and involvement

A fundamental part of the certification process is making sure employees are adequately trained and are aware of their role in the food safety management system. This helps not only improve consistency of process but also creates a more engaged workforce.

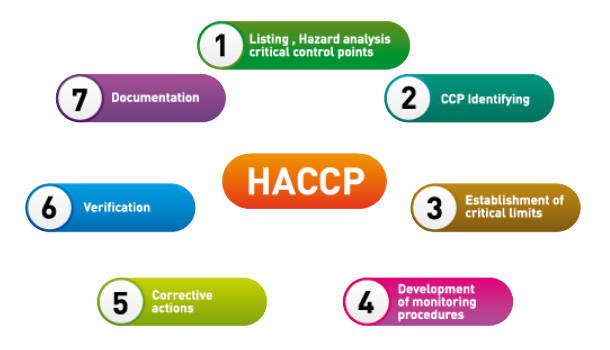

What are the 7 stages of Haccp?

Seven basic principles are employed in the development of HACCP plans that meet the stated goal. These principles include hazard analysis, CCP identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping and documentation.

- Principle 1 - Conduct a Hazard Analysis. ...

- Principle 2 - Identify the Critical Control Points. ...

- Principle 3 - Establish Critical Limits. ...

- Principle 4- Monitor CCP. ...

- Principle 5 - Establish Corrective Action. ...

- Principle 6 - Verification. ...

- Principle 7 - Recordkeeping. ...

- HACCP Does not Stand Alone.

Principle 1 - Conduct a Hazard Analysis

The application of this principle involves listing the steps in the process and identifying where significant hazards are likely to Occur. The HACCP team will focus on hazards that can be prevented, eliminated or controlled by the HACCP plan. A justification for including or excluding the hazard is reported and possible control measures are identified.

Principle 2 - Identify the Critical Control Points

A critical control point (CCP) is a point, step or procedure at which control can be applied and a food safety hazard can be prevented, eliminated or reduced to acceptable levels. The HACCP team will use a CCP decision tree to help identify the critical control points in the process. A critical control point may control more that one food safety hazard or in some cases more than one CCP is needed to control a single hazard. The number of CCP's needed depends on the processing steps and the control needed to assure food safety.

Principle 3 - Establish Critical Limits

A critical limit (CL) is the maximum and/or minimum value to which a biological, chemical, or physical parameter must be controlled at a CCP to prevent, eliminate, or reduce to an acceptable level the occurrence of a food safety hazard. The critical limit is usually a measure such as time, temperature, water activity (Aw), pH, weight, or some other measure that is based on scientific literature and/or regulatory standards.

Principle 4- Monitor CCP

The HACCP team will describe monitoring procedures for the measurement of the critical limit at each critical control point. Monitoring procedures should describe how the measurement will be taken, when the measurement is taken, who is responsible for the measurement and how frequently the measurement is taken during production.

Principle 5 - Establish Corrective Action

Corrective actions are the procedures that are followed when a deviation in a critical limit occurs. The HACCP team will identify the steps that will be taken to prevent potentially hazardous food from entering the food chain and the steps that are needed to correct the process. This usually includes identification of the problems and the steps taken to assure that the problem will not occur again.

Principle 6 - Verification

Those activities, other than monitoring, that determine the validity of the HACCP plan and that the system is operating according to the plan. The HACCP team may identify activities such as auditing of CCP's, record review, prior shipment review, instrument calibration and product testing as part of the verification activities.

Principle 7 - Recordkeeping

A key component of the HACCP plan is recording information that can be used to prove that the a food was produced safely. The records also need to include information about the HACCP plan. Record should include information on the HACCP Team, product description, flow diagrams, the hazard analysis, the CCP's identified, Critical Limits, Monitoring System, Corrective Actions, Recordkeeping Procedures, and Verification Procedures.

HACCP Does not Stand Alone

The application of HACCP does not stand alone in a food processing facility. The plan must be built on other food safety programs. Good Manufacturing Practices (GMP) that are practiced by the processing facility will support HACCP plan and will address food safety and food quality issues that are not critical for the reduction of food safety hazards. Sanitation Standard Operating Procedures (SSOP's) are required in federally inspected meat and poultry operations and address procedures for clean facilities, equipment and personnel that are necessary for all products produced in a facility.

Benefits of HACCP Certification

The preventive approach of HACCP based procedures not only improves food safety management but also complements other quality management systems. The mainbenefits of HACCP based procedures are: Saves your business money in the long run. Avoids you poisoning your customers

Advantages of HACCP

The HACCP system can be applied throughout the food chain from the primary producer to the final consumer. Besides enhancing food safety, other benefits in applying HACCP include more effective use of resources and more timely response to food safety problems. In addition, the application of the HACCP system can aid inspection by food control regulatory authorities and promote international trade by increasing buyer confidence in food safety.

A HACCP plan is specific to a particular food and processing application. The HACCP system is capable of accommodating change, such as advances in equipment design, processing procedures or technological developments.

The successful application of HACCP requires the full commitment and involvement of management and the workforce. It also requires a team approach. The application of the HACCP system is compatible with the implementation of quality management systems, such as the International Organization for Standardization’s ISO 9000 series, and is the system of choice in the management of food safety within such systems.

- Saves your business money in the long run

- Avoids you poisoning your customers

- Food safety standards increase

- Ensures you are compliant with the law

- Food quality standards increase

- Organises your process to produce safe food

- Organises your staff promoting teamwork and efficiency

- Due diligence defence in court.

Reduction in product loss

Prerequisite programs, such as Standard Operating Procedures (SOPs), are the foundation of HACCP. SOPs are written procedures that accurately describe and detail essential job tasks. The use of SOP pre-operations and cleanup checklists help ensure the steps throughout the production process are done correctly, resulting in fewer mistakes.

Increase in product quality

By identifying and controlling potential hazards, such as microbiological, chemical and physical contaminants, the company can better assure consumers that its products are safe. By reducing hazards, you maintain a clean record, which in turn will strengthen the company’s public image.

Better inventory control

The required prerequisite program checklists layout in establish monitoring procedures, detailing the correct way to complete the job, taking the guessing work out of it. Prerequisite programs must be continuously documented by the designated employee and reviewed by the company to ensure HACCP compliance. During review, personnel can monitor and correct purchase specifications.

Consistency in product preparation

As part of the HACCP system critical control points, at which a control can be applied to prevent a hazard, are identified. From there critical, measurable limits of acceptability are outlined for each critical control point, as well as monitoring procedures. These steps guarantee product consistency. However, if the criteria is not met and deviation occurs, the product will either be corrected or disposed of.

Increase in profit

The costs of implementing and operating a HACCP system vary depending on the requirements the facility needs for compliance. But the investment will contribute to profitability, here’s why: by applying all seven of the HACCP principles, safe and quality products will be produced, earning the trust of customers who will continue to keep purchasing the product.

In summary, taking action to ensure the safety of the food being produced has a ripple effect of positive outcomes. It all starts with the implementation of prerequisite programs, which set the stage for applying HACCP principles.

Keep in mind, this isn’t a set it and forget it system! If the correct procedures are not constantly enforced, documented and maintained, hazards are bound to occur. Leniency could result in noncompliance, a recall or even a foodborne illness outbreak.

Who can use HACCP?

All businesses involved in the food supply chain from producers to retailers can use HACCP. Enterprises include, but are not restricted to, those linked with:

|

Fruits & Vegetables |

Meat & Meat Products |

|

Dairy Products |

Spices & Condiments |

|

Fish & Fishery Products |

Cereals |

|

Nuts & Nut Products |

Restaurants |

|

Bakery & Confectionary |

Fast Food Operations etc. |

|

Hotels |

|

Types of Hazards

There are four types of hazards that you need to consider:

Microbiological hazards

Microbiological hazards include bacteria, yeasts, moulds and viruses.

Chemical hazards

Chemical hazards include water, food contact materials, cleaning agents, pest control substances, contaminants (environmental, agricultural and process e.g. acrylamide), pesticides, biocides and food additives.

Physical hazards

Physical hazards include glass, packaging, jewellery, pest droppings, screws etc.

Allergens

This refers to the risk associated with the unintended presence of one or more of the

Process of Haccp Certification

The 12 Steps To Develop A HACCP Plan

- Assemble the HACCP Team. ...

- Describe the Product. ...

- Identify the Intended Use and Consumers. ...

- Construct Flow Diagram to Describe the Process. ...

- On-Site Confirmation of Flow Diagram. ...

- Conduct a Hazard Analysis (Principle 1) ...

- Determine Critical Control Points (CCPs) (Principle 2) ...

- Establish Critical Limits for Each CCP (Principle 3)

Food Safety Policy and Objectives

- Documents needed for the effective development, implementation and updating of the FSMS

- A documented PRP program

- Documentation of raw materials, ingredients and product contact materials

- Characteristics of end products

- Intended use of end products

- Flow diagrams for products or process categories

- Description of process steps and control measures

- Methodology and parameters used for selection of control measures

- HACCP Plan

- Procedure for Corrections

- Procedure for Corrective Action

- Procedure for Control of Nonconforming Product

- Procedure for Withdrawals

- Procedure for Internal Audits

- Procedure for Document Control

- Procedure for Records Control

HACCP Certification Process

- Application review and contract Sign up between KB MANAGEMENT SERVICE and applicant organization.

- Onsite Audit and off site Audit

- Certification decision

- Issue of certificate.

- Surveillance audit (annually or Half yearly as finalized during application review process and agreed by client)

- Re-Certification Audit (within three years before expiry of certificate)

Required Documents for HACCP Certification

1 Any type Registration of Firm,Company)

2 Adhar Card Of Main Applicant

3 Product list with index

4 Production Plan

5 Gst Certificate Copy

6 Current Copy Of Sale Purchase Invoice

Time Period of Provide Certificate In Hand

One Day Working

One Day working with Applicant Regarding Complete process of Documents Sets

Two working Day

Check the all Documents and Audit File For processing the Certification and onsite Audit

One Day working

Provide Draft Copy of Certification and wait the final decision of Applicant

One Day Working

One Day working Get Final Soft copy of certificate

5 Day working

Congratulating for Hard Copy by Courier